Topic RSS

Topic RSS

8:02 am

October 24, 2011

Offline

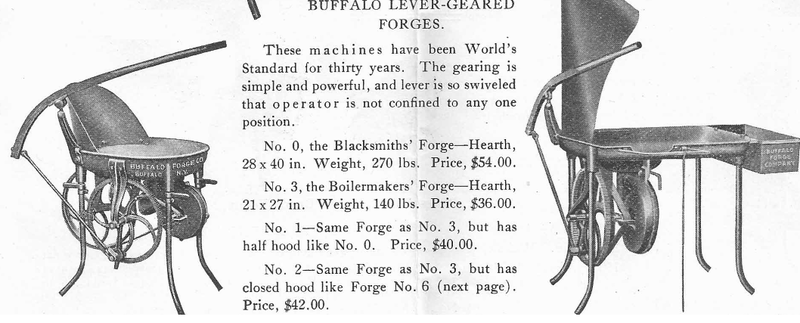

OfflineI recently picked up complete Buffalo #3 boilermaker forge and have found some info stating that it should be lined with refractory clay or refractory cement.

Where can one get these refractory materials, locally in the PNW?

How thick of a layer is needed?

Should the cement be formed around the tuyere to create a fire pot?

7:52 pm

NWBA Member

December 27, 2014

Offline

OfflineI have a small coal forge that I have lined with some clay I dug up from our yard, and it works well as an insulator. Of course, that is far deeper than mine, and I also set a brake drum in the middle of mine to act as the pot. What you could do is get some fire brick and make a pot with that, and maybe put some bricks in the rest just to build it up. It can get pretty heavy if one adds too much stuff in it though, so I can't say what you would personally want.

I do know that refractory cement is rather expensive, even if it is mixed with plaster of Paris or regular cement. Haven't looked it up myself, really, so I'm afraid I can't really say.

My Youtube channel: Cave of Skarzs

Just having some fun messing around with whatever I have a mind to do.

12:13 pm

NWBA Member

Board Member

April 26, 2010

Offline

Offline9:27 pm

May 21, 2015

Offline

OfflineNow I'm wondering about this. My forge has a cast iron bed, about 2'x3'x2'' deep. Probably a bit smaller than Peter Ross's forge for comparison. I see he has his bed lined, I'm wondering if it's something I should do, perhaps even trowel a thinnish layer into the tueyere? I'm thinking local clay mixed with sand or grog for most of it, and maybe fireclay or refractory around the tueyere?

It would make for a deeper fire, but I wonder how much coal I'd be raking off the edges. If I get any feedback on this, I can take some pictures, and try to figure out how to post them. I'm better with old technology than new.

Most Users Ever Online: 668

Currently Online:

10 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

Larry L: 1566

Grant: 1420

Bruce Macmillan: 625

Lee Cordochorea: 595

Lynn Gledhill: 572

JNewman: 520

Gene C: 504

J Wilson: 426

Eric Sprado: 383

Tom Allyn: 340

Member Stats:

Guest Posters: 22

Members: 8723

Moderators: 4

Admins: 1

Forum Stats:

Groups: 23

Forums: 97

Topics: 3537

Posts: 20288

Newest Members:

fred.f.chopin, RuoYi, rodeoneerer, NWBABjorn, mddangelo, Nevillberger, Crusty Veteran, redwoodforgeoakland, Jimekalmiya, George_KelleyModerators: Steve McGrew: 77, N.W.B.A.: 72, webmaster: 0, bluehost: 0

Administrators: admin: 540

Log In

Log In Register

Register Home

Home

Usage Policy

Usage Policy